NEW! McClain's now offers two oil-based relief inks!

Caligo Safe Wash Relief Ink |

|

Gamblin Relief Ink |

|

|

|

Our search for a high quality oil based relief ink took more than two years and instead of finding just one ink, we found two that work exceptionally well.

Both Caligo and Gamblin Relief Inks are suitable for all types of relief printing, including woodcut, linocut, wood engraving, monotype and photopolymer plates including Solarplates. They both give excellent coverage and work right out of the tube or can without modification. |

| |

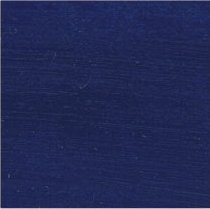

| Caligo Safe Wash Relief Ink |

Caligo Inks, a family owned business located in Wales, UK has been serving printers for over 30 years and offers and extensive line of high quality artists printmaking inks. Their Safe Wash line gives printmakers a linseed oil based ink that can be cleaned up with soap and water instead of solvents. Emulsifiers added into the ink makes this possible. Of the oil based/soap and water clean up inks we have tried, this one stands out for consistent working properties and excellent coverage.

The clean up process for Caligo Safe Wash Inks is totally non-toxic and extremely easy. First, remove excess ink from the brayer by rolling it across newsprint and from the glass slab by scraping it with a Red Devil Scraper. Second, use a liquid soap like Savvy Soap along with a nail brush to break up the ink. Third, when all the ink is loose, run under warm water using the nail brush to assist with the ink removal. It's that easy!

In 1999, Caligo Inks was recognized as the Welsh Small Environmental Company of the Year for the development of their environmentally friendly Safe Wash Inks. |

| |

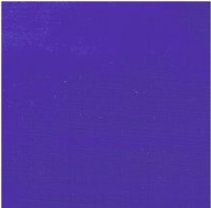

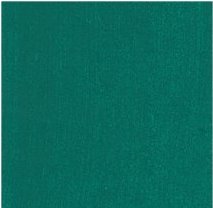

| Gamblin Relief Ink |

Gamblin Artists Colors, in Portland, Oregon, is world famous for their professional quality oil colors. Since 1980 Robert Gamblin has been formulating traditional, pure, linseed oil artists colors for artists and conservators. He designed new production machinery that allows the incorporation of an extraordinary amount of pigment into the base, improving texture and creating luscious, intense, rich colors. This same skill and attention to quality was applied to creating Gamblin Relief Inks.

Gamblin Relief Inks don't contain fillers or modifiers so they are less tacky than most inks. When it comes to cleaning up, most of the ink is easily removed with a dry cloth. Any residue can be removed with Gamsol Odorless Mineral Spirits, the safest odorless mineral spirits we've found.

McClain's worked closely with Robert Gamblin and Gamblin Artists Colors in developing Gamblin Relief Ink and the palette was carefully constructed to create maximum color mixing ability. We are very excited to offer you this classic relief ink. |

| |

| TIPS______________________________________________ |

| Toning & Sealing Woodblocks |

Toning and sealing woodblocks is not essential but it can be helpful. Toning the block creates contrast so you can see the image develop as you carve. Sealing the block keeps the ink from soaking down into the wood, which means better coverage plus you can change colors easily. Also, cleaners and linseed oil in the ink can sometimes soften wood or bring up the wood grain, causing a loss of crisp detail. Sealing the block prevents this from happening.

Woodblocks can be toned and sealed using various methods but we prefer the following. |

To start you will need:

gloves

woodblock

a dab of black oil based ink

about 3 tablespoons of Gamsol Odorless Mineral Spirits

1 ink knife

3 clean cloths like Dynacloths

wipe-on polyurathane

1 strip of fine grit sand paper

1 block of wood |

|

step 1:

With an ink knife, mix a dab of black oil based ink with Gamsol odorless mineral spirits |

|

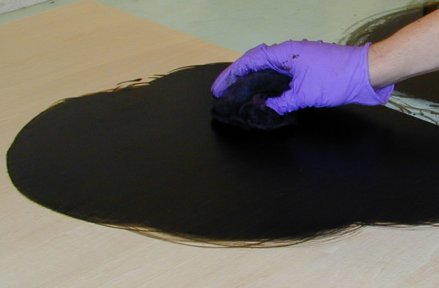

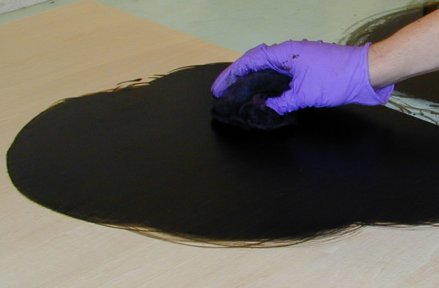

step 2:

Using a soft dynacloth pick up the ink/mineral spirits mixture |

|

step 3:

Apply the ink and mineral spirits mixture in a circular pattern over the entire face of the woodblock |

|

step 4:

When the block is completely covered use a clean rag to remove any excess. You should easily be able to see the grain of the wood. This allows you to use media like carbon paper or graphite to transfer the image to your block and still be able to see it. |

|

step 5:

Apply wipe-on polyurathane (wipe-on polyurathane creates fewer streaks than brush-on polyurathanes). Wipe in a circular pattern with a clean cloth and let dry. Repeat this step two to four times until the entire block is sealed.

If the woodblock is large it may begin to warp. If this happens both sides of the block must be coated with polyurathane. |

|

step 6:

When the final coat of polyurathane is dry (at least an hour) sand the entire block. To make a sanding block wrap a block of wood with fine sand paper. Sand the block to knock down any wood fibers that may have popped up and create a smooth surface. |

| NEWS______________________________________________ |

|

McClain's will be at this year's Southern Graphics Council Conference (March 25-29) in Chicago Illinois.

We hope to see you there!

*Look for our show special on tools and the latest tattoo!*

|

|

|

| ___________________________________________________ |

Richard Steiner and Mort

working on a block

|

2009 Moku Hanga Workshop with Richard Steiner!

August 17-21 in Portland, Oregon.

Sign up early and SAVE!

Sign up by May 1st and pay $400. After May 1st the cost goes up to $425 so sign up now. |

|

|